Across the spectrum of electronics, from smartphones to medical monitoring devices, modern electronic products require precision components that are small, conductive, corrosion-resistant, and reliable. The most practical material available for many of these applications is brass, processed through CNC machining to the high tolerances and precision demanded by the electronics industry.

In this article, we will discuss how and why brass CNC machining is essential in today's electronics industry, which parts you are likely to find made of brass, and how suppliers like LJZ CNC ensure reliability and consistency.

Brass as a Material for Electronics

Brass, an alloy of copper and zinc, is helpful in electronics because it combines conductivity, strength, and machinability (and can be milled to a polished surface). All of the conductive components used in electronic products like circuit boards, chargers, and hand-held devices must have these properties, but not all solid materials do.

| Property | Key Advantage for Your Electronics |

|---|---|

| Excellent Electrical Conductivity | Ensures reliable and efficient signal transmission with minimal power loss. |

| Durable Strength | Provides the necessary structural stability for robust connectors, terminals, and durable mechanical contacts. |

| Inherent Corrosion Resistance | Guarantees a long operational lifespan and consistent performance, even in humid or demanding environments. |

| Superb Machinability | Enables the production of intricate designs with precise dimensions and the ability to hold exceptionally tight tolerances. |

| Non-Magnetic Nature | Prevents electromagnetic interference (EMI), making it perfect for sensitive circuits, sensors, and audio components. |

Learn more about brass machining techniques here →

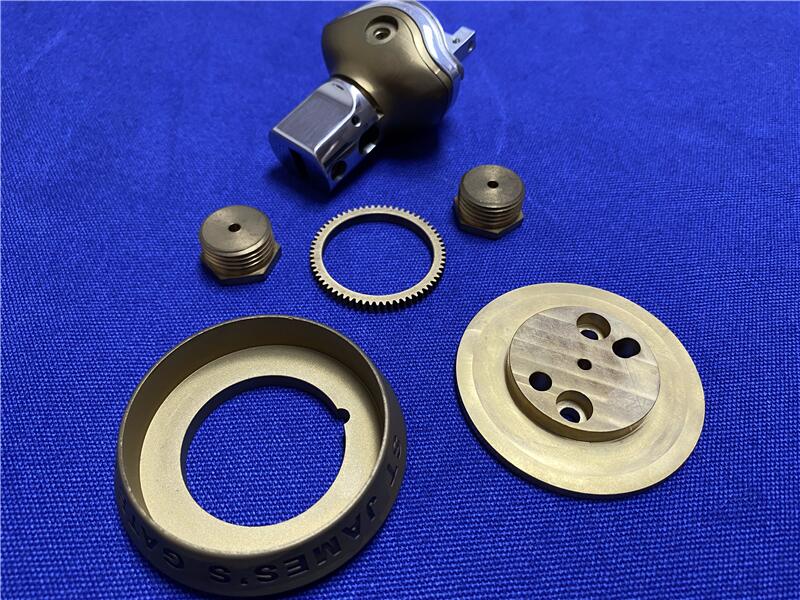

Typically CNC Brass Parts Used in Electronics

CNC machining allows for an incredibly high level of precision for brass parts used in electronics. Here are some examples:

Brass CNC Connectors

Used in cables, PCBs, charging ports, and modular interfaces.

Terminal Pins & Contact Probes

Necessary for stable electrical connections for circuit boards, chargers, and testing devices.

Brass Sensor Housings

Instruments that require pressure, humidity, and position sensors (to name a few) usually have brass comprised of an EMI shield for wall thickness and protection.

Custom Micro Brass Parts

These precision parts have tiny features for wearables, medical diagnostic devices, and IoT devices.

The parts above are great examples of parts that require CNC precision. CNC precision provides repeatability, dimensional tolerance and smooth surface finish necessary for electronics assembly.

Brass vs Other Materials in Electronics

| Material | Strengths | Limitations |

|---|---|---|

| Brass | Conductive, corrosion-resistant, easy to machine | Slightly heavier than aluminum |

| Copper | Very conductive | Too soft for mechanical use |

| Aluminum | Lightweight | Poor conductivity, harder to solder |

| Plastic | Insulating, lightweight | Non-conductive, less durable |

Verdict: Brass offers the best balance for conductive mechanical parts that must also endure heat, vibration, and precise mating.

Why CNC Machining is an Ideal Process for Brass Electronic Parts

Brass electronic parts must meet precise accuracy requirements. In general, the brass components will need to meet:

±0.005mm tolerances

Smooth finish to allow for solder or press-fit

Zero burrs in any interior or exterior parts to avoid short-circuits

You want to use CNC machining because:

Automated precision with well-defined and tight repeatability

Short-run time for prototypes, or custom short-runs, or multiple runs

Can scale for high-volume production runs, with lower tool wear

Have the ability to create custom threads, slots, and holes for terminal blocks and enclosures

At LJZ CNC, we manufacture micro-size brass products for clients in the electronics manufacturing sector around the world, some with extremely demanding tolerances.

Case Example: CNC Machined Brass Connector for Smart Sensor

Industry: Smart home electronics

Part: Micro brass socket housing (Ø 3 mm diameter, used thread M4)

Material: H59 Brass

Requirements:

±0.005 mm tolerance

Deburr-free finish

50,000 pcs/month delivery

Solution:

We used Swiss turning combined with ultrasonic cleaning to provide our customer with batch-ready parts, with a 99.5% pass rate on solder-ready surfaces and RoHS compliant brass.

Fortifying Internal Links

This article supports the overall definition of core electronics manufacturing capabilities of LJZ CNC.

You can also have a look at:

Our Brass Machining Capabilities

Do you need CNC Brass Parts for your Project in Electronics?

If you are starting a project involving electronic devices that will require high-precision components made of brass, you have found a supplier. All the processes used by LJZ CNC are ISO9001-certified, so you know we follow strict and disciplined tolerances in our machining. We will be happy to consider flexible production batches based on the contemporary manufacturing landscape.

Contact us now for free DFM feedback and quotes within 24 hours.