Aluminum CNC machining is a great option for CNC machining. Aluminum alloy materials are favored by engineers in various industries, and aluminum machined parts are commonly used in CNC machining due to its high machinability. Aluminum can be quickly and easily cut by machine tools, and deforms less which leads to higher accuracy. China aluminum parts machining is widely used to create specified precision parts in various industries today.

Aluminum machining supplier LJZ offers a complete China aluminum machined service. As one of the most professional china aluminum machining manufacturers in the world, we can produce complex china machining aluminum parts with different types of Aluminum.

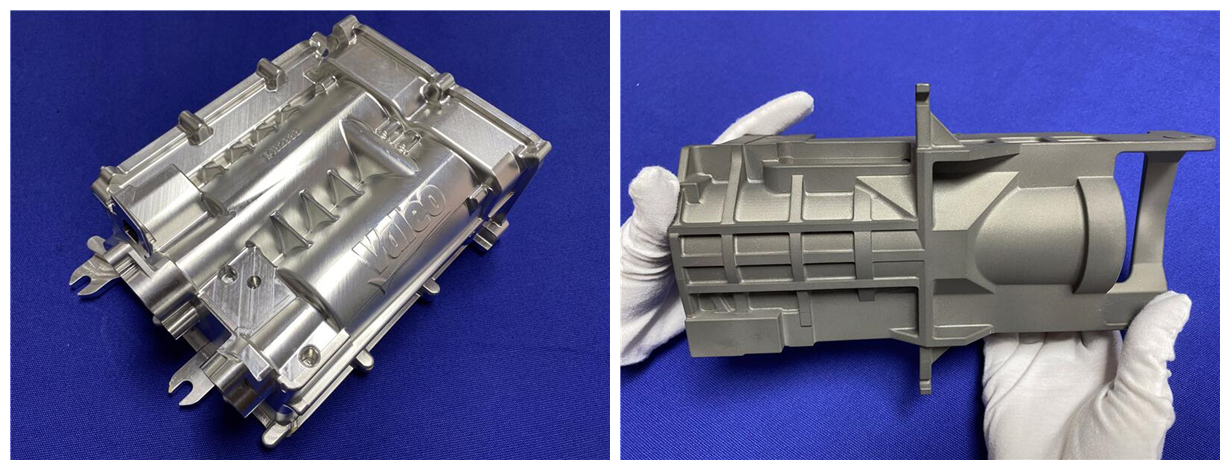

Due to the good fluidity and plasticity of aluminum alloy, casting on die casting machine, aluminum parts machining die casting machine CNC machining processing a variety of complex shapes, which can produce higher precision and surface quality. To a large extent, the castings and China aluminum machining services or custom China aluminium machining part are great, and also save electricity, metal materials, and labor costs. Choose China aluminum machining manufacturers, We can offer you cheap custom cost of machining aluminum.

At LJZ modern machine shop, we focus on providing aluminum precision machining service. Equipped with high-tech machines, including turning and milling machines, grinding, multi-axis such as 5-axis machining, 5-axis turning and milling etc. We are able to take the job of precision aluminum machining in a very quick turn.

As relyable China aluminum machining parts supplier, LJZ has passed ISO 9001, ISO16949, ISO13485 sertificates. This proves that LJZ has a perfect management system and manufacturing system to ensure quality aluminum machining and production. We are proud that we can fully compliant with the exacting requirements of our customers, strict compliance with PPAP and process FMEA for automotive customers and meet demanding requirements from medical customers!

CNC aluminum parts are widely popular in almost every industry due to its excellent machinability. Another benefit of aluminum machined parts is that there are many options for its surface treatment, such as:

Anodizing

Powder spraying

Painting

Polishing

Sandblasting

Laser engraving

And many more

Two important factors affecting the cost of CNC machining Aluminum are the complexity and size of the part and the type of Aluminum. LJZ is a professional China aluminium cnc parts supplier, and we would take full account into the cost details of CNC machining aluminum (including design, machinery, labor and raw material costs). Welcome to make an inquiry!

Aluminium grades should be considered when choosing China aluminum machined technology. In recent years, due to its high strength-to-weight ratio, good corrosion resistance, good formability, and aesthetic appeal, aluminium die casting parts has increased its popularity. Since aluminum CNC parts are used in various industries, so selecting the most suitable China machining aluminum becomes more important.

As an expert aluminum machining supplier, we are familiar with the characteristics of each aluminum. Aluminium machining part supplier LJZ has always steeped ourselves in developing aluminum parts manufacturing. Below are some of the china aluminum machining part commonly used in our daily machining:

AL 2000 series

2011, 2014 2017 2024

AL 3000 series

3004 3018 3104 3105 3105 3040

AL 4000 series

4032 4043

AL 5000 series

5005 5052 5082 5083

AL 6000 series

machining 6061 aluminum, 6063 6040

AL 7000 series

7072, machining 7075 aluminum

Due to the soft and easy processing characteristics of aluminum profiles, special attention should be paid to deformation during CNC processing.

1. Select reasonable fixtures and control the fixture force.

Reasonable fixture and control force can reduce unnecessary positioning errors. China aluminum parts supplier LJZ suggested that high-level engineers should be employed to carry out preliminary preparations such as fixture installation. Selecting special fixture tools and controlling the force during clamping can also improve the clamping method of aluminum profiles.

2. Select the appropriate tool and optimize it.

Because the aluminum profile is relatively soft, it is easy to deform during cutting. The material and geometric parameters of cutting tools have an important influence on the cutting force and heat of materials. We suggested that a larger chip space should be provided to ensure the normal operation of the tool, and the teeth number of the tool should be as small as possible.

3. Select a reasonable cutting amount and control the cutting speed.

The cutting speed should be controlled according to the hardness of the aluminum material, cutting state, material type, cutting depth, etc. This will effectively reduce the wear of the machine.

4. Use a special cutting emulsifier for aluminum alloy.

The professional cutting emulsifier can play the role of cooling, lubrication, cleaning, etc. in aluminum parts processing. This will be more helpful for producing aluminum parts.

Aluminum alloys are produced with so many grades that are mainly based on alloying elements and material properties. The naming convention uses four digits. The first digit of the number identifies the class or series of alloy(ex. 1xxx, 2xx.x, and 3xxx) , and the other three digits describe specific alloys, related hardening processes, and other useful information. Aluminum machined supplier LJZ will introduce you the following types:

2000 series: 2017, 2024, 2A12 etc

Features: It is called duralumin, has high strength, good cutting performance, can be heat treated.

Applications: aircraft structures, aerospace, weapons, engines, pistons, automobile bodies, ship hulls and stress components, etc.

5000 series: common brands: 5052, 5083, 5754, 5182

Features: The main alloying element is Mg. It has good processing and molding performance, corrosion resistance, welding performance, fatigue strength and marine climate resistance.

Application: It is mainly used for building decoration, pressure vessels, ship structures and offshore facilities, aircraft fuel tanks, automobile fuel tanks, automobile gas reservoirs, containers, etc.

Example: AL5052 has good seawater corrosion resistance and excellent machinability. Often used in marine environments, such as ship hulls, gangways. and other marine equipment, etc.

6000 series: 6061, 6063, 6082, etc.

Features: The main alloy elements are magnesium and silicon, with medium strength, good corrosion resistance, weldability and oxidation effect.

Application: mainly used in construction, ships, rail vehicles, electronics, electrical appliances, durable consumer goods and other fields.

Example: AL6061 has good weldability, formability and machinability. At the same time, it has medium strength and maintains good operability after annealing. Mainly used in aerospace fixtures, electrical fixtures, communications, etc.

7000 series: 7075, 7050, etc

Features: Super hard aluminum alloy series, the main alloy elements are zinc, magnesium and copper. Deformed aluminum alloy plates with excellent heat treatment effect and ultra-high strength have good plasticity after solid melting treatment, and have good mechanical properties, wear resistance and fatigue resistance.

Application: mainly used in aerospace, auto parts, machinery, mold, etc.

Example: AL7075 is one of the strongest commercial alloys. It has strong corrosion resistance and is the best for aviation and marine plates. It's ideal for highly stressed parts. Mainly used in aerospace industry.

The main differences between machining 7075 aluminum and machining 6061 aluminum are the following properties.

Aluminum series and chemical composition:

machining 6061 aluminum has a higher silicon content, while machining 7075 aluminum has a higher zinc content. When looking at the exact range of data for both aluminum, it can also be seen that both aluminum contain a significant amount of magnesium, although machining 7075 aluminum has a slightly higher magnesium content.

Mechanical Properties:

When looking at the two aluminum in the -T6 heat treatment condition, some significant differences can be seen. The first is that the tensile strength of 7075-T6 is almost twice that of 6061-T6. The second is that the shear strength of 7075-T6 is approximately 1.5 times that of 6061-T6.

Fabrication Considerations:

The lower hardness and tensile strength make machining 6061 aluminum easier to manufacture than machining 7075 aluminum. machining 6061 aluminum is weldable, while machining 7075 aluminum is generally considered to be non-weldable.

Application Areas:

Both aluminum are used for bicycle parts, aerospace parts and architectural structures. However, their specific uses in these areas differ.

From the outside, different aluminum are indistinguishable by the naked eyes which greatly affects the quality of products. In order to ensure the authenticity of raw materials, LJZ is equipped with spectrometer which is able to strictly detect raw materials with testing report. Moreover, we also provide SGS material certificate according to customer's requirements.

Need Custom Aluminum Machining? Request a quote Now!

Swiss CNC Machining is a modern precision manufacturing process, which can produce very small parts quickly with tight tolerances and extreme accuracy. LJZ has 100+ state of the art Swiss turns and this helps us to produce million of swiss turned parts of in every month.

Precision CNC machining utilizes various tools and equipment such as CNC Swiss machines, 3,4,5 axis machines, horizontal and vertical milling, CNC turning technologies to remove raw materials to manufacture certain parts or assemblies. Which are suitable for machining complex aluminum parts with tight tolerances.

EDM uses the electric discharge generated between two electrodes to remove material from the workpiece. Although it can process any conductive materials such as aluminum and stainless steel. But because of cost, it's often used to machine harder and more difficult materials.

China custom aluminum parts are widely used in automobile manufacturing, internal combustion engine production, motorcycle manufacturing, motor manufacturing, oil pump manufacturing, transmission machinery manufacturing, precision instruments, landscaping, electrical construction, architectural decoration and other industries. China custom aluminum parts manufacturers offer excellent thermal conductivity, small specific gravity, high machinability conditions, control these conditions can ensure high quality custom aluminium parts CNC machining.

The advantages shown by aluminum alloy in density, tensile strength, elongation, corrosion resistance, etc. make it the most widely used non-ferrous metal material in industry, and it plays a pivotal role in aviation, aerospace, automobile, machinery manufacturing and other industries. LJZ is a professional custom cnc aluminum factory, inquiry CNC Aluminum China.

Aircraft components

Automotive components

Medical Devices

Optical Parts

Aluminum Gears

Worm Gears

Aluminum enclosure

Aluminum Housings

Aluminum Panels

Spline Shafts

And many more

You've come to us to expect high-quality, efficient,and excellent service, and that's what you will get from us!

LJZ has conducted long-term in-depth and extensive theoretical research and practical verification, and has accumulated rich experience in the process of overcoming difficulties. Choose LJZ as your China aluminum machining supplier at bulk wholesale cost of machining aluminum

Get in touch with us

We will contact you within 24 hours

We are committed to providing rapid prototyping, CNC machining, Swiss machining, plastic injection molding, gear machining services. Contact us to get more info!