For product materials and product quality, we strictly implement LJZ inspection procedures and standards or ISO related standards, which include material inspection reports, FAI, CMM final inspection reports, and corresponding reports required by clients from various industries, such as PPAP, FMEA etc. Our ultimate goal is to make our product 100% safe to use.

Quality Inspection and Testing

All incoming materials must be inspected by spectrum detector to ensure the authenticity.

Each product needs to go through a first article inspection (FAI) and be verified by engineering or quality managers.

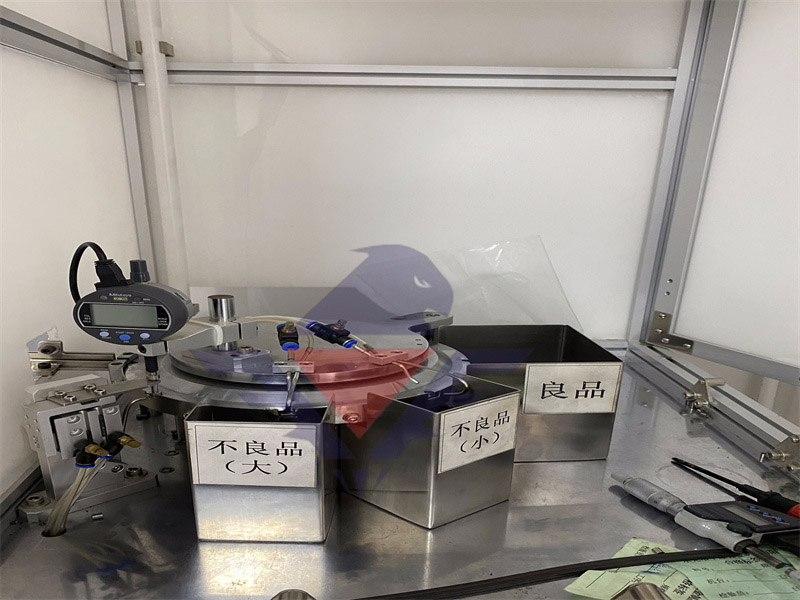

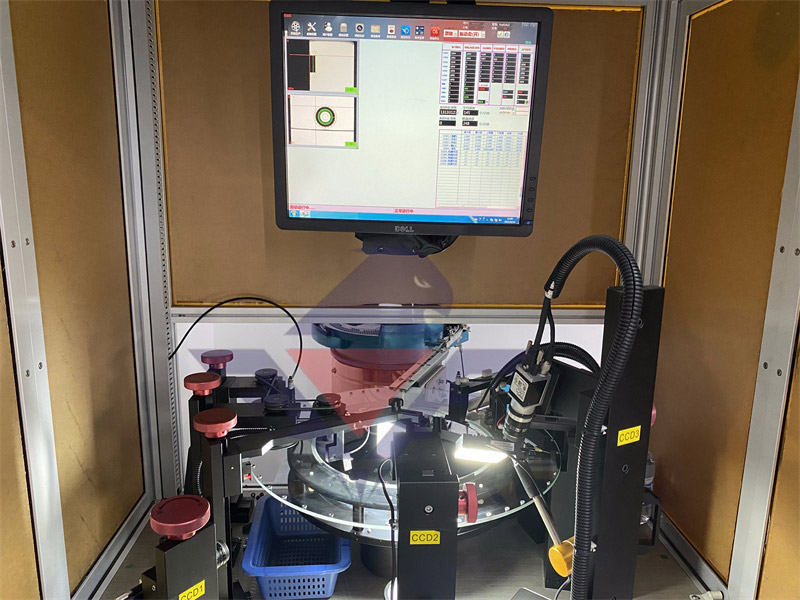

Before warehousing, 100% of the products must be inspected

Check again and record the delivery report before shipment

Regularly calibrate and identify inspection on equipment

Calipers

Inside/Outside diameter micrometer

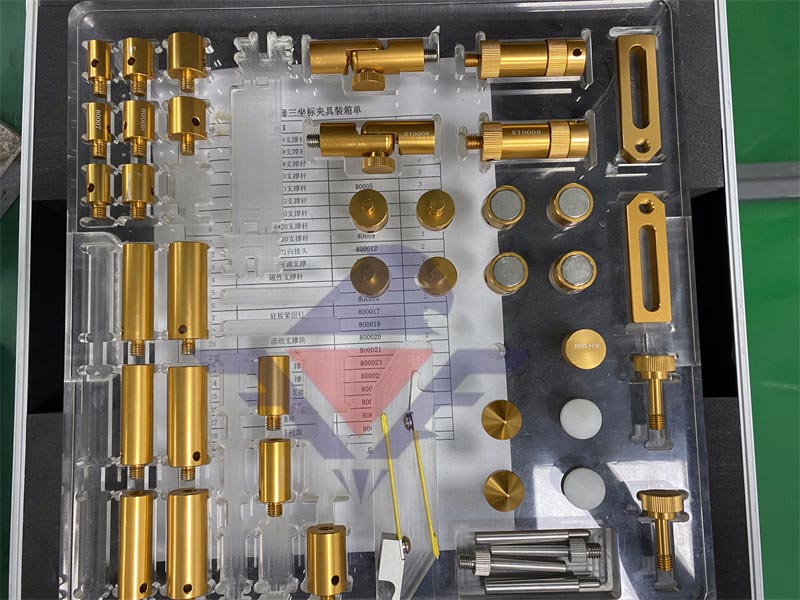

Pin gauge/Gauge block / Plug gauge

Thread/plug gauge (Metric/inch)

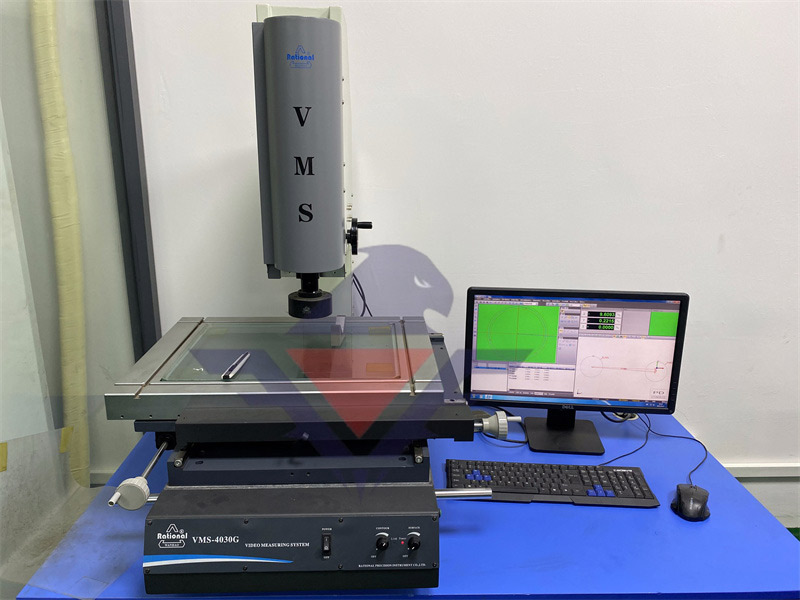

Projector

Material spectrometer

Hardness tester

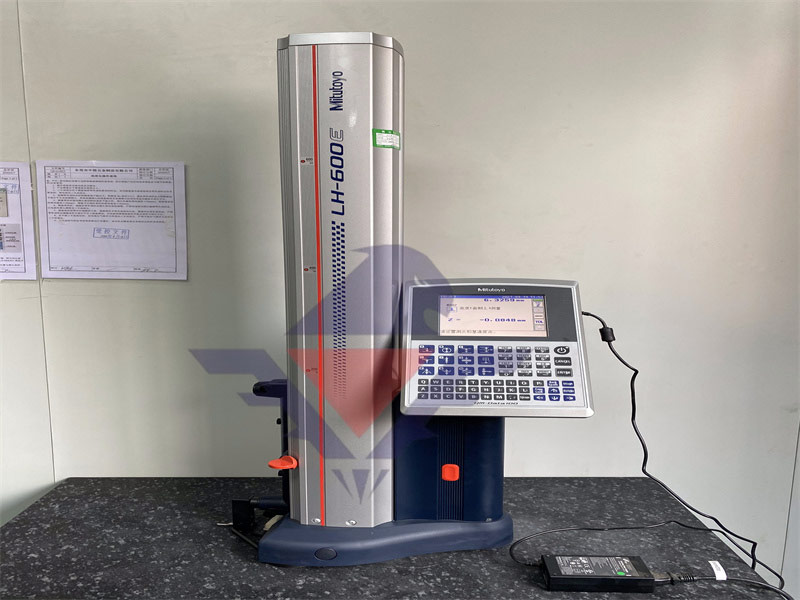

It is a device accurately measures the geometry of an object along X, Y and Z axes using a touch-trigger, scanning or vision probe to take a series of precise points on the surface of some complex and precise workpieces. For some complex and precise parts, it can complete parts inspection, shape measurement, process control and other tasks through continuous scanning. Our CMM is now widely used in inspecting precision parts, mold and moldings.

After finishing the surface treatment of parts, it is necessary to check whether the size and appearance meet the requirements. Customized packaging ensures that the product will not be damaged during delivery.

Improving customer satisfaction is our first priority, meanwhile, we fully compliant with the latest ISO requirements to evaluate and prevent any possible risks before production, which enable us to offer our customers with defect free products and services. Besides, regularly follow-up visit, telephone, survey are our tradition to continuously improve and upgrade our team.