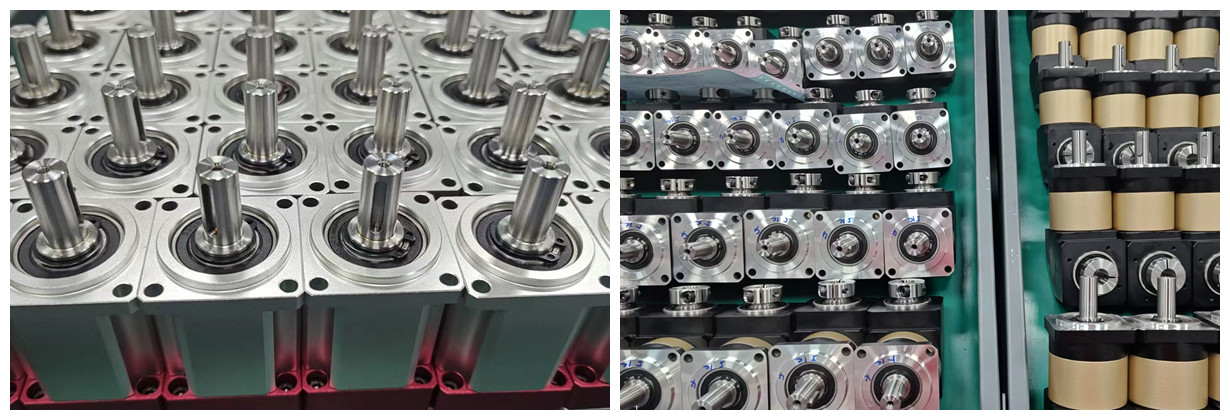

CNC Gears is the process to obtain the specific structure and precision of gears by the general precision CNC machining method. Gears are the core transmission components of mechanical equipment. The quality will have a direct impact on the vibration, noise and reliability of mechanical products, and sometimes become a key factor restricting the improvement on product levels. Therefore, it is very important to choose an excellent gear manufacturing supplier. LJZ company focuses on providing high-precision gear manufacturing services for various industries.

Gear manufacturing steps include forging, normalizing, turning, rolling, gear shaving, heat treatment, grinding. The purpose of normalizing process is to prepare for the final heat treatment to effectively reduce the deformation of heat treatment.

Gears manufactured by CNC machining involve precise and automated cutting processes. The key steps include:

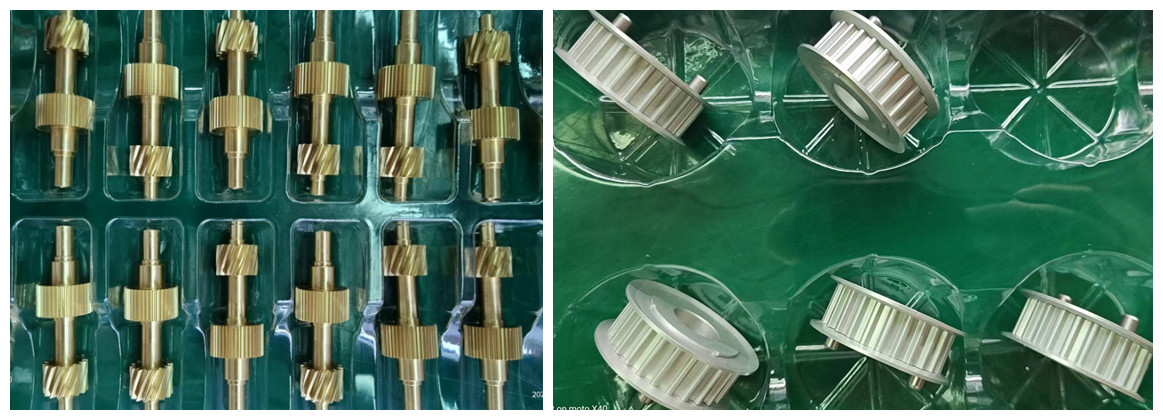

Material Selection and Preparation: A suitable material, such as steel or aluminum, is chosen and cut into a gear blank.

CNC Programming: A CAD model of the gear is created and converted into CNC programming code. This code guides the CNC machine's operations.

Machining: The gear blank is fixed in a CNC machine, where various cutting tools shape the gear teeth. Common methods include milling and hobbing. The CNC machine ensures high precision and repeatability.

Finishing: After the teeth are cut, the gear may undergo additional processes like grinding to achieve the desired surface finish and dimensional accuracy.

Quality Control: The finished gears are inspected using tools like coordinate measuring machines (CMM) to ensure they meet specifications.

CNC machining is favored for its precision, flexibility, and ability to produce complex gear geometries efficiently.

ISO management system-LJZ has a wealth of experience and strong design team, as well as supporting hardware equipment. Our gear cutting companies' production management follows ISO and automobile quality management system, pursuing high-precision, stable and durable products.

Powerful CNC equipment-equipped with advanced German CNC production machines including gear turning and milling, Swiss machining, hobbing, grinding, etc. In-house inspection and testing equipment includes Hexagon CMM, runout tester, gear tester, etc. The measurement accuracy can reach ISO 1 grade.

Quality assurance-a variety of testing standards, including stringent material testing, in-processing-inspection, finished product random checking, and final testing. Regular staff training and promotion.

Our capabilities-Expert in manufacturing of small and medium module gears, Modulus 0.3-15, Size 0-1000mm, and DIN 5-9 accuracy.

For every precision machined gear, including the most complex mass production, its materials must pass our most professional testing and inspection. The materials that we often work with are:

Aluminum alloy, Alloy steel, Copper, Stainless steel, POM, Nylon, PMMA, ABS, PEEK, and more.

Workpiece materials using gear machining are divided into several main groups according to ISO standards, each group has unique machinability properties. Steel is the largest material group in the metal cutting range. Stainless steel is an alloy material with a chromium content of not less than 12%. Heat resistant premium alloys include many high alloy iron, nickel, cobalt and titanium based materials.

Workpiece materials using gear machining are divided into several main groups according to ISO standards, each group has unique machinability properties. Steel is the largest material group in the metal cutting range. Stainless steel is an alloy material with a chromium content of not less than 12%. Heat resistant premium alloys include many high alloy iron, nickel, cobalt and titanium based materials.

Industrial Gear Manufacturing Types-How to Apply

The difficulty of gear manufacturing has discouraged many companies, except us. Instrument manufacturers realized that when producing a large number of reliable, punctual and cost-effective gears, LJZ can always achieve their goals. Our gear products and services are welcomed by the following industries:

Reducer

Robot

Our gear manufacturing service is widely used in family service robot, commercial robot, medical and health robot, special robot, logistics robot and many robots.

Auto

Engine accessories: throttle body, cylinder block, tensioning wheel

Transmission system accessories: clutch, transmission, reducer, magnetic materials

Brake accessories: brake master pump, brake sub pump

Medical

Hospital commonly used medical instruments: trauma treatment vehicle, operating table, operating lamp, monitor, anesthesia machine, ventilator, and so on

Precision Instrument

Measuring instrument, automobile instrument, ionizing radiation instrument, marine instrument, aviation instrument, navigation instrument, driving instrument, radio test instrument and so on.

ETC

As a professional company in CNC machining, our gear cutting service is widely used in ETC antenna, ETC controller, ETC settlement platform, etc.

Related Machining Service

Get in touch with us

We will contact you within 24 hours

We are committed to providing rapid prototyping, CNC machining, Swiss machining, plastic injection molding, gear machining services. Contact us to get more info!