Medical device or equipment requires high precision dimensions, real materials, and specified surface treatments. LJZ provides medical CNC machining medical services for a medical device or machined products for a long time. With rich experience in medical CNC machining and assembly for medical applications, our excellent international team is helping more and more medical machining companies by providing rapid prototyping, small batch production and solving delivery, quality, assembly and other problems.

For ease of use, engineers often design sophisticated medical products with different shapes, which cannot be completed by CNC milling service and quick turn CNC machining alone. LJZ medical machining company is equipped with the most complete processing technology, such as: Turning and milling, internal and external grinding, surface grinding, WEDM/EDM, Swiss turning, plastic injection molding and so on.

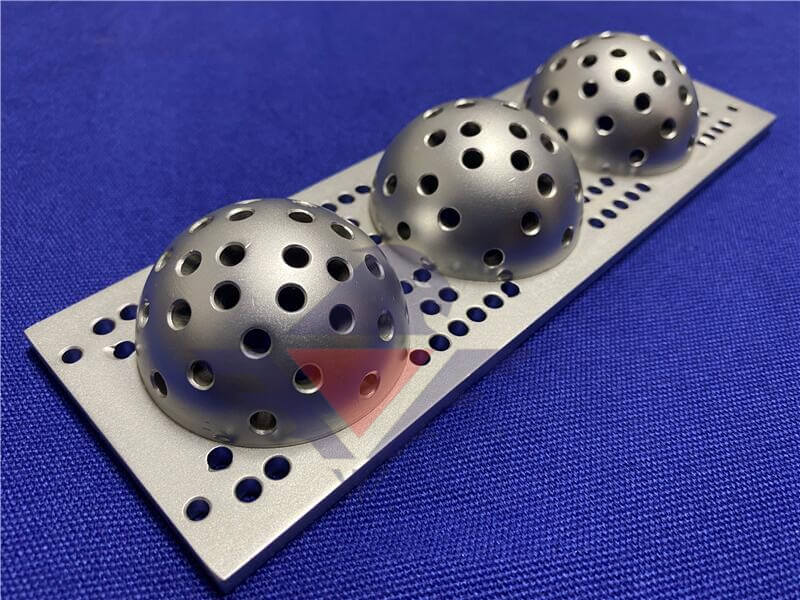

Since medical device products are in close contact with the human body, the safest and environmentally friendly surface finishes are required. Common surface treatments that we work with are includeing anodizing, electropolish surface finish, passivation, sandblasting surface finish, laser carving, painting, and so on.

To produce ideal precision parts with high quality, suitable, and high-grade raw materials are required. Therefore, LJZ is very strict in the selection of materials for medical products, all input materials must be tested by the spectrum analyzer. Our commonly used materials are including aluminum, wire EDM titanium, china stainless steel machining, PMMA, PEEK, PEI, and so on.

In addition to precision CNC machining and high-volume Swiss machining service. LJZ also provides a series of services for CNC medical machining equipment R&D and manufacturing, which includes medical prototype development, small-batch rapid tooling or low volume CNC manufacturing, and high volume medical injection molding.

Our professional engineering team makes key design adjustments through design for manufacturability (DFM) feedback for each quotation, thereby saving development time and costs. Choose from hundreds of medical grade plastics, metals, and elastic materials. We are able to finish affordable rapid prototyping parts or small batch production in one day as soon as possible to simplify your supply chain before and after the product is put on the market.

In order to meet the stringent standards of customers in the medical industry, we have obtained ISO13485, built a clean room and trained professional medical injection molding personnel, which means that we are qualified to engage in the R&D, processing and production of medical parts and clean room injection molding equipment. Our CNC medical machining molding manufacturing expert team can help you quickly transform FDA Class I and Class II devices or non-structural components from prototypes to production.

The recognition of our healthcare customers comes from our professional services and trustworthy quality assurance,we are proud of this.

ISO 9001 and 13485 standards.

Rapid prototype machining, precision CNC Swiss machining and medical injection molding solutions for medical clients.

Strict compliance with PPAP.

Strict production control, quality control and excellent after-sales service.

Need engineering support for CNC medical machining projects? Start with a free quote today!

Related Industries

Related Machining Service