Plastic injection molding is a method of injecting molten plastic material into mold cavity under high pressure at a certain temperature, then cooling and solidifying to obtain a molded product. This method is suitable for mass production of parts with complex shapes. It is one of the most important manufacturing methods. The advantages of injection molding are fast production, high efficiency, and automatic, which is suitable for mass production. As an experienced company dedicated to offering precision plastic injection molding in china, LJZ takes full advantage of latest precision plastic injection molding technology, management system, and reliable quality, which won us the favor of customers from various industries who need injection molding services. We hope to bring you our advanced China precision plastic injection molding.

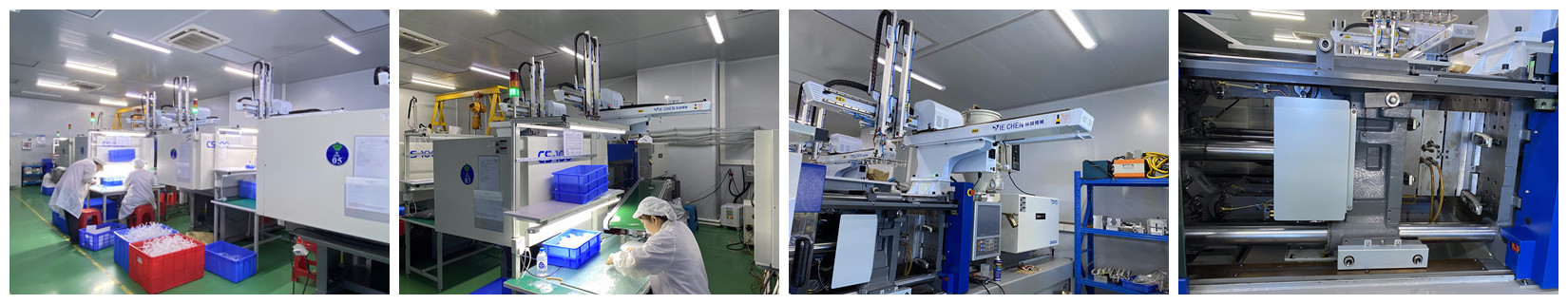

We take pride that we have strictly implemented ISO standards for many years, meanwhile, we attach great importance to the clean room environment and the corresponding quality control system.

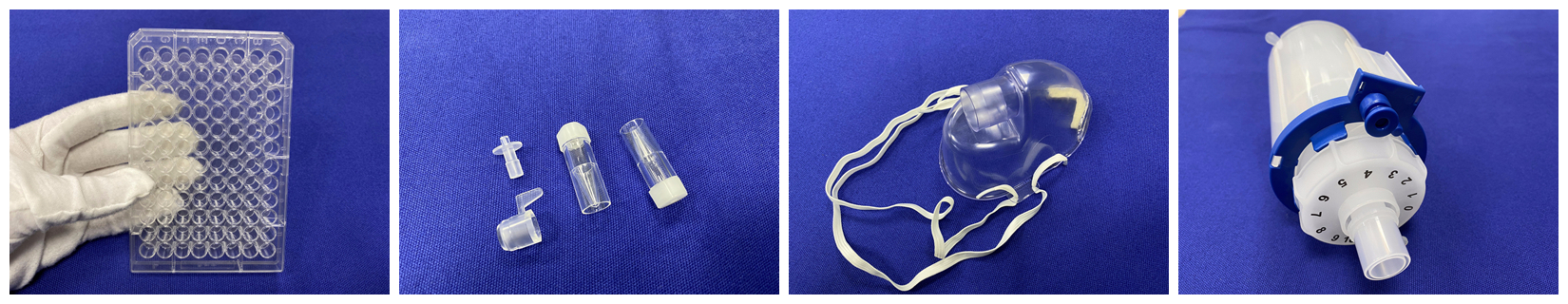

Medical R&D requires long-term test and verify. We are committed to one-stop CNC machining and rapid tooling service for medical device protoyping development and small batch production run which will greatly help engineers shorten the development cycle. LJZ is an expert in providing you such medical injection molding China.

We can provide professional medical prototyping and plastic injection molding services. In precision injection molding, the mold is one of the keys to obtain precision plastic products that meet the quality requirements. The mold for precision injection molding should truly meet the requirements of medical products' size, accuracy and shape. Use appropriate mold size tolerances to prevent molding shrinkage errors; at the same time, plastic injection mold and molding prevent injection deformation and demold deformation, improve the accuracy of medical prototypes, and maintain the accuracy of medical prototypes.

Materials for Rapid Tooling and Plastic Injection Molds

The materials that we often use to make molds are: S136H, 2316H, H13, 2316H, P20, 8407 (hardened), and NAK80 (hardened). In addition, we provide standard SPI surface treatment, EDM texture, and a series of etching textures.

Materials for Medical Plastic Molding

Our injection molding materials include ABS, PC, PP, and other plastics. There are hundreds of thermoformed and thermoset plastics for you to choose from. For more information, please check our material table for reference. Here are common plastics that we work with:

ABS, ABS/PC, Acetal, Acetal Copolymer, Acetal Homopolymer, Nylon, PEEK, PEI, PET, PMMA, Polycarbonate, Polypropylene, And Not Limited.

We have invested in ISO clean room and trained professional medical injection molding staff to meet the strict requirements for medical parts. Our medical molding manufacturing expert team can provide you with solutions from prototyping to mass production in a quick turn.

As a professional plastic injection molding service manufacturer, our clean room injection molding production and assembly have the following strict requirements. Determine the location of the line and waterway, and reserve the equipment interface. Plan the feeding method and the turnover area of raw materials. Determine the storage area of the products in production for each team and mark them for visual management. Clarify the recycling process of the lower corner of the material handle.

Certification: ISO 13485

Clean Rooms: Class 8 rooms available

Rapid tooling: small batch production available

Mass production: On demand manufacturing and stock plan for million parts

Process Validation: standardized verification packages, industry-recognized agreements or customer-defined methods

The radiation effect and ripple effect of the expansion and extension of plastic insert molding in medical molding are sufficient to affect the medical industry structure, product structure, specialized division of labor methods, mechanical processing methods and management models, social production division, and enterprise operating mechanisms. Come profound changes.

LJZ implements "One Man, One Mold" policy--- One trained employee is responsible for one specified mold. FAI and CMM inspections, which are critical to quality, will be tracked and checked to ensure the safe use of parts. In addition, we will provide you with tracking tooling options and quality report.

| Prototyping | On-Demand Manufacturing | |

| Objective | Prototypes or small batch production needs for R&D | On demand manufacturing needs for volume production |

| Timing | Complete design or material iterations Evaluate costs, reduce design risks Improve R&D productivity Speed up product into market QTY<2,000 | Design and evaluation have been completed to reduce supply risk, quality and total cost Appraisal documents needed Mold capability information |

| Mold Cavities | Single or None | Single or Multi-cavity |

| Mold Service Life | Limited, at least 2K shots | Millions |

| Mold Storage | 18 months | 3 years |

| Mold Ownership | As per contract | Yes |

| Quality Reports | QC reports as requsted | F.A.I reports First 30 pcs full dimensions inspection In-Processing-Inspection in every 2 hours CMM measurement technology PPAP, IQ/OQ/PQ, ISO13485 |

Plastic injection molding, also known as injection molding, is a molding method that combines injection and molding. The advantages of plastic injection molding are fast production speed, high efficiency, operation can be automated, variety of designs and colors, shapes can be from simple to complex, sizes can be from large to small, and the product size is accurate, the product is easy to update, and it can be made into complex shapes. Plastic insert molding are suitable for mass production and molding processing fields such as products with complex shapes.

Related Machining Service

Get in touch with us

We will contact you within 24 hours

We are committed to providing rapid prototyping, CNC machining, Swiss machining, plastic injection molding, gear machining services. Contact us to get more info!