Find types of custom CNC machining service in LJZ, a professional CNC machining manufacturer in China. We supply CNC machining aluminum/stainless steel/china plastic CNC machining/brass/copper/titanium, produce high quality precision CNC machining parts with 3/4/5 axis CNC machining service. Cheap price/cost. Inquiry Now!

With hundreds of CNC machines, our unparalleled in-house production capacity ensures that your parts are delivered globally on time and in time.

At LJZ modern CNC machine shop, we are ISO9001 and ISO13485 certified, our CNC machining facilities are designed for efficiency and precision.

Quick-turn prototypes can be delivered in 1 day at the fastest, batch CNC parts can be delivered in 5-15 days. Inquiry LJZ CNC prototyping factory.

General accuracy is +-0.01mm, limit accuracy is +-0.001mm, which can meet your high precision requirements. Authentic and reliable material inspection reports (SGS), first inspection report (F.A.I), and surface finishes inspection guarantee our machined components are safe to use.

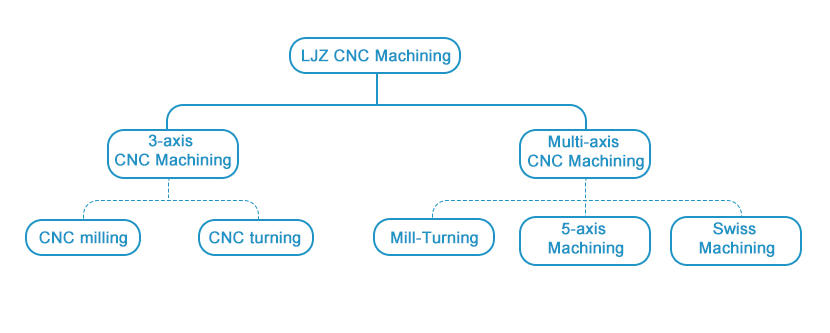

LJZ dedicated in China CNC service for many years today will take you dive into more details into types of CNC Maching. CNC machines can be divided into two basic classifications: 3-axis and multi-axis machines. 3-axis machines including CNC Milling Machines and CNC Turning Machines allow cutting tools to move along straight three-dimensional vectors; Multi-axis CNC machines are similar to 3-axis machines but with a higher degree of freedom in mechanical movements.

As one of the most experienced China CNC machining suppliers, LJZ has premium China CNC machining including CNC Milling, CNC Turning and CNC Swiss Machining machines for sale. We are committed to providing outstanding CNC service China, so if you are interested in our CNC machines wholesale, please feel free to contact us!

CNC milling, one of the precise component machining methods. CNC milling services china involves a rotating milling cutter that moves on the surface of the workpiece to produce the desired shape, by using different kinds of milling methods such as plain milling and angular milling.

Custom CNC Machining Price >

CNC turning, a processing mainly for symmetrical or cylindrical component making. The cutting tool works in a linear way, and the rotation of work piece is realized with the help of computer numerical control. Different materials can be handled by this accurate machining.

CNC Turning Service Price >

CNC Swiss machining by LJZ, a reliable CNC processing service company in China, is a modern ultra high precision CNC manufacturing technique. It deals with very small parts with extreme accuracy. Our CNC Swiss micro machining services are widely used in different industries.

CNC Machining Services Price >

Video of CNC Machining China Factory

LJZ CNC Machining | Characteristics |

CNC Milling |

|

CNC Turning |

|

CNC Swiss Machining |

|

CNC stands for Computerized Numerical Control. CNC machining generally refers to precision machining. To be more precise, CNC precision machining is a subtractive manufacturing process that uses various precision cutting tools and machines to remove raw materials to make certain parts or components. CNC machining is suitable for a wide range of materials such as titanium, aluminum, stainless steel, brass or copper and surface finish, which can all be achieved by China CNC machining supplier LJZ. CNC Machining finds application in a variety of industries, for example: cnc machining prototype, cnc machining aerospace parts, aerospace cnc machine and so on.

As a reliable custom precision CNC machining company in China, LJZ has experienced engineers that are able to machine different types of materials such as titanium, brass/copper, through our CNC machining and formulate suitable process for each product. CNC machined products' accuracy can be controlled between 0.01 and 0.005 (mm) to meet your precision requests. If you take interest in china cnc machining service, do contact us for more information, and we are sure that LJZ, one of the most professional China precision cnc machining suppliers would provide you with the most satisfied China cnc machining service.

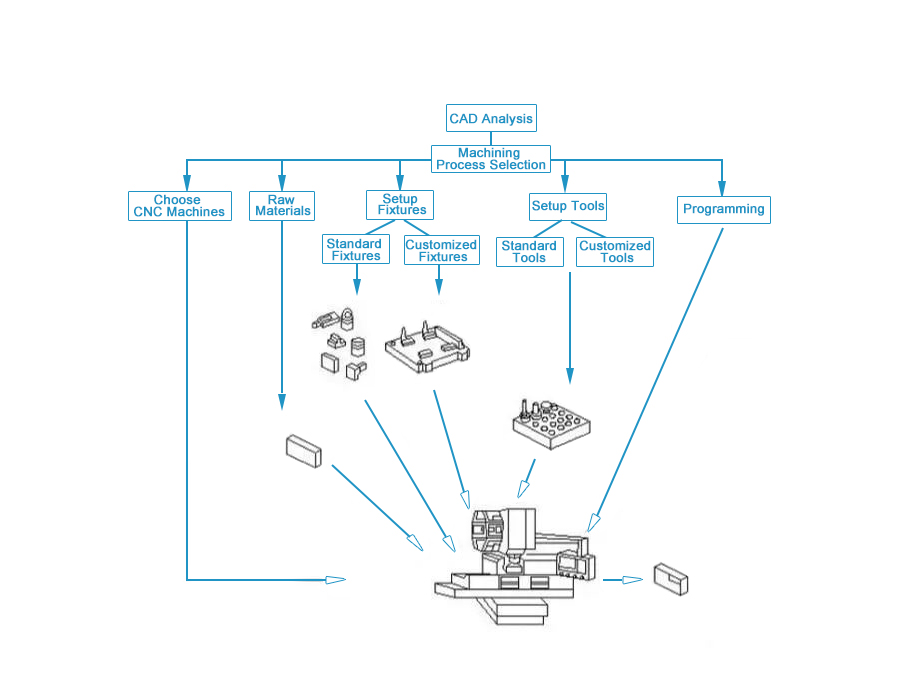

CNC(Computerized Numerical Control)machining, also known as precision machining. CNC machining process is simply the combination of CNC machine and Computerized Numerical Control systems. By input program, CNC machine works under the control of computer to obtain high quality, high precision and complex machined products. LJZ precision CNC machining process includes CNC milling, CNC turning, Grinding, EDM/Wire EDM, etc.

① Drawing analysis: analysis CAD model, i.e. 2D&3D drawings, choose the best machining process.

② Programming: convert CAD files into CNC programs, program can be simply understood as the language that CNC machine can read. Input program into CNC machine.

③ Setup: check and calibrate CNC machine and tools, and setup tools and raw material in CNC machine.

④ Operating: CNC Operators start machines to make the drawings into products.

CNC VS 3d Printing and CNC Machining VS Injection Molding are topics which many people want to know, today LJZ China CNC Machining Supplier will take you on a quick journey into the world of CNC machining and its related technology. There are five aspects we will talk about:

① Processing method;

② Material selection;

③ Speed;

④ Cost;

⑤ Precision.

First, for CNC Machining:

CNC machining usually uses subtraction. Use a fast rotating tool to remove unwanted material from the raw material.

CNC can use a variety of materials, and almost all solid materials can be processed with CNC.

Small batch processing takes longer than 3D processing. However, CNC processing time is particularly advantageous in large batches.

For volume orders, CNC production costs are lower.

The finished parts have high precision and excellent surface quality.

Then, for 3d Printing:

3D printing usually uses addition. Create products layer by layer with 3D printing materials on a blank panel.

Most of the materials used for CNC can also be used for 3D printing. However, 3D printers which can process metals are very expensive.

The processing time of large batches is longer than that of CNC. However, 3D printing processing time has advantages in small batches.

For small batch orders, 3D printing costs are lower.

The finished parts have low precision and poor surface quality.

Last, for Injection Molding:

Injection molding is to dissolve the granular plastic, and then press the liquid plastic into the mold through high pressure. The corresponding parts can be obtained after cooling.

Thermoplastic and thermosetting plastics are generally used, such as ABS/PE/PC/nylon/TPE/rubber and other daily plastics.

It is suitable for mass processing, but needs to make molds. Compared with CNC processing, the delivery time of injection molding is longer.

Large batch processing has great advantages, and the single piece price is low. However, there is mold cost.

The surface precision is extremely high, and the shape error of the same batch of products is very small.

1. A 90 degree internal angle is recommended to be changed to an arced R angle. Due to the characteristics of CNC CNC tools, it is difficult to machine 90 degree right angles. Therefore, we usually recommend our customer change the design to R angle. Or use EDM to make 90 degree right angles, but at a higher cost.

2. Keep the ratio of drilling depth to diameter less than 8. Even for special drills, it is difficult to maintain strict tolerances during production.

3. Increase the depth of design by 25% when drilling blind holes. if the design depth isn't enough in production, there will be a drilling point at the bottom of the part.

4. Avoid thin walls as much as possible. It is difficult to control the tolerance of thin wall. It is suggested to increase the wall thickness appropriately. Or EDM can be used with high cost.

5. Share with us the purpose and the functionality required of the part. We are pleased to recommend the most suitable raw material and processing plan for you.

Fast delivery time

Stable High precision

Machinable complex parts

High processing efficiency

New product R&D and shape modification

LJZ, a reliable CNC machining service supplier in China, provides precise CNC machining & China custom CNC machining to meet your needs for different product quantities from 1-off prototype to 100,000 CNC products. Choose us, the brilliant China cnc machining manufacturer, you will get quick turn cnc machining,excellent China machining service, rapid and fast CNC machining with low cost. Also China CNC service has the following advantages:

Very suitable for new product development and modification. If you want to change the shape and size of the part, you only need to modify the part processing program.

High efficiency and stable quality, highly accurate and repeatable.

Economical and fast turnaround.

Suitable for machining complex parts with tight tolerance.

As a professional CNC aluminum parts factory, LJZ is capable of handling the complex aluminum machining and fabrication with high precision and accuracy. At our factory in china, we have advanced machines for custom CNC aluminum parts, whose power spindles enable us to cut aluminum at a rather high speed. With smaller cutting tools, every fine detail can be taken into consideration during the machining process. As a reputable CNC machining company in China, we are so experienced in CNC aluminum parts machining service that even the most challenging tasks can be handled by us with ease and cheap CNC machining service.

Besides our CNC machining factory in China, we also have a rich material library, as many as 475 kinds of materials available. Common materials that can be handled through our CNC machining service are mainly a variety of metals and plastics: aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, ABS, PEEK, Acrylic, Delrin, Polycarbonate, Polypropylene, Hdpe etc. In addition, to ensure the authenticity of the materials, our CNC machining service are equipped with a spectrum analyzer and can provide SGS material test reports. About the selection and application of so many different materials, we also has prepared relevant PDF files for our customers to refer to.

In order to protect the product from rust and corrosion, or for the exquisite appearance of the product, besides precise CNC machining and manufacturing, whether the machined parts are in large or small batch cnc machining, it is usually necessary to do the corresponding surface treatment. LJZ CNC machine service company have rich experience in 30+ surface treatments. Common ones are : anodizing, sandblasting, electroplating, powder spraying, painting, laser engraving, silk printing, blackening, polishing, etc.

Quality Guarantee

LJZ CNC machining services manufacturer strictly implement the ISO 9001,ISO13485 quality management system, at least 6 inspection procedures from raw material processing to shipment. QC pass rate is 98%!

Delivery Guarantee

150+ CNC machines work day and night. China CNC machining factory's dynamic milling technology promotes 50% machining efficiency. Each order follows up by professionally trained merchandiser, which ensure products will be delivered to customer in time and on time.

Production Capacity Guarantee

1,500,000 pcs average monthly CNC milled and turned production capacity with global delivery.

CNC machining services manufacturers prototypes deliver in 1-5 days, volume CNC production delivers in 5-20 days depending on quantity.

Service Guarantee

50+ international professional engineers and sales teams provide technical support and solutions in one day; Dedicated personnel to follow up custom CNC machining companies logistics information to ensure that the products reach your hands safely.

Most China CNC machining company relies on software programs to work. It is a kind of computer aided machining. CAM creates the NC code and path for cutting tools to follow. To run the CNC machine, it is necessary for users to require certain knowledge about the programs, especially the knowledge of NC code, the numerical control code.

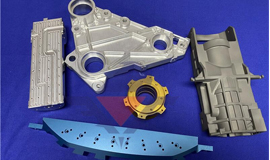

Various pictures and images of customized precision CNC machining products can be found in our gallery part. From CNC milling, turning to Swiss machining, we continuously provide high quality service for our customers.

As a professional high volume CNC machining company, we can handle a variety of materials. The common material for our CNC machining are metals like copper. LZJ can also handle several plastics such as PEEK. Other mediums include foams, woods, etc.

Our CNC machining products are used in a wide range of industries: medical, military, automobile, aerospace and information industry, etc. Many equipment like diagnosis and treatment equipment relies on CNC machining technology for better controlling and processing.

The acceptable range a work piece deviate from its intended shape is the tolerance in CNC machining. As a professional company specializing in precision CNC machining service, we produce desired parts with tight tolerance and extreme accuracy.

CNC Machining is the use of CNC machines such as CNC mill or CNC turn to process metals or plastics to obtain high precision parts. The parts produced by CNC machining are very accurate and repeatable.

CNC machining generally refers to high precision CNC machining. Common precision CNC machining methods include CNC milling, CNC turning, 5 axis machining, Swiss turning, EDM, WEDM, grinding etc.

The cost of CNC machining mainly depends on the complexity of product structure and tolerance requirements. A more complex custom CNC machining product request higher accuracy and higher the price. Accordingly, more product demanding means a more economical price.

There are many kinds of surface treatments for CNC machined parts such as anodizing, coating, polishing, bead blasting, blacken, plating etc. However, the surface treatments on each material are limited. For example, CNC machined aluminum parts are most suitable for anodizing, while steel parts are suitable for polishing or heat treatment.

Do You Need A Consultation?

Start your partnership with LJZ.