In recent years, CNC auto parts machining industry is developing fast and getting attention to more and more countries, and we are very optimistic about the prospects of machining CNC auto parts industry. We have been providing CNC machining automotive parts for many years for SHENZHEN BYD. At the same time, more and more CNC auto parts manufacturers are cooperating with us to accelerate the development of new CNC car parts and bring them to the market faster.

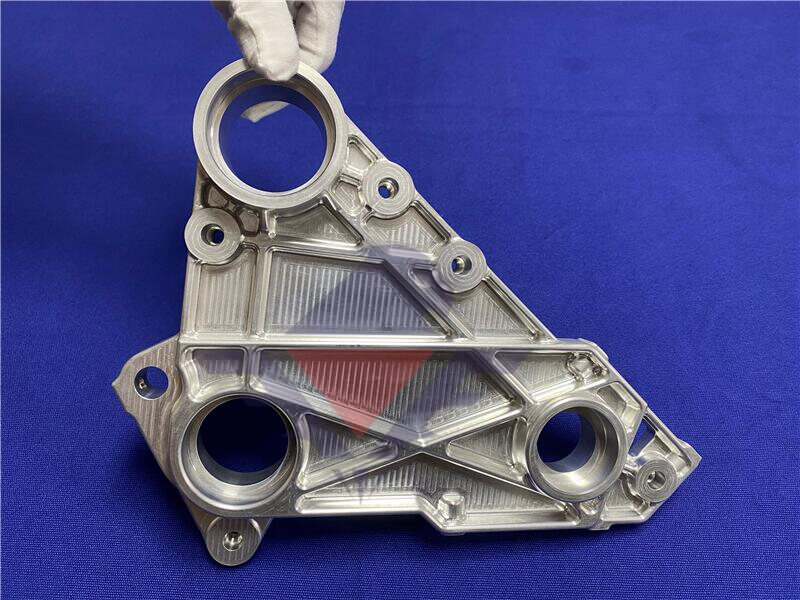

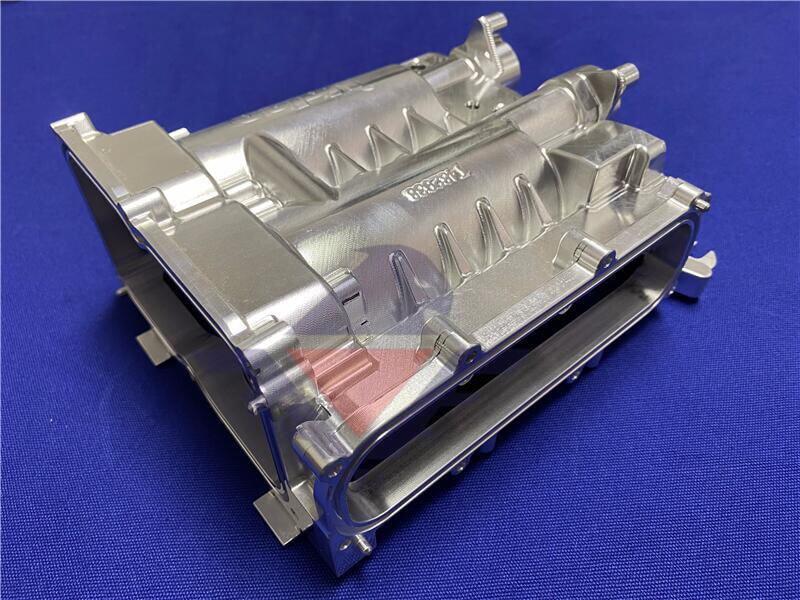

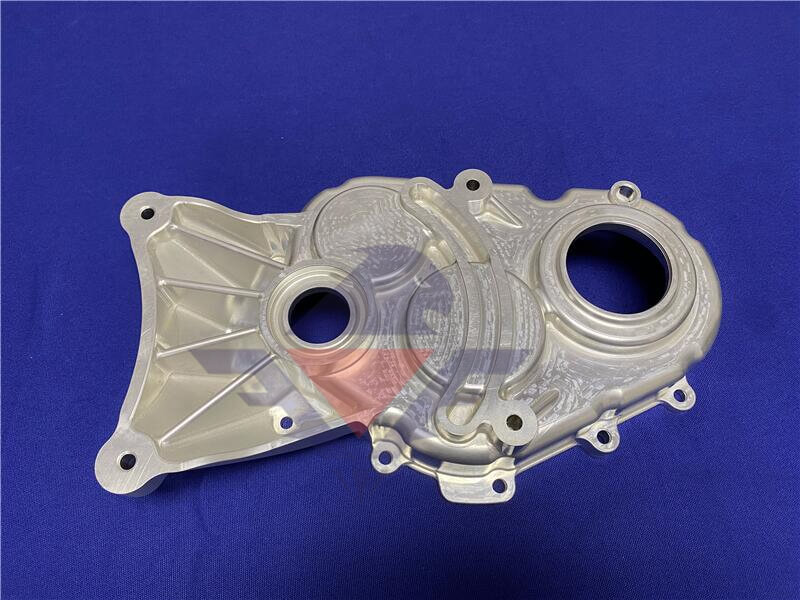

As a machining CNC auto parts manufacturer,our newly designed automotive CNC auto part are diverse and complex. LJZ is good at the flexible use of multiple technologies and skills for CNC machining car parts. Our CNC car parts manufacturers' precision machining technology includes: CNC Swiss machining, CNC quick turn CNC machining and milling, Multi spindle cam automatics, CNC grinding, EDM/WEDM, and so on.

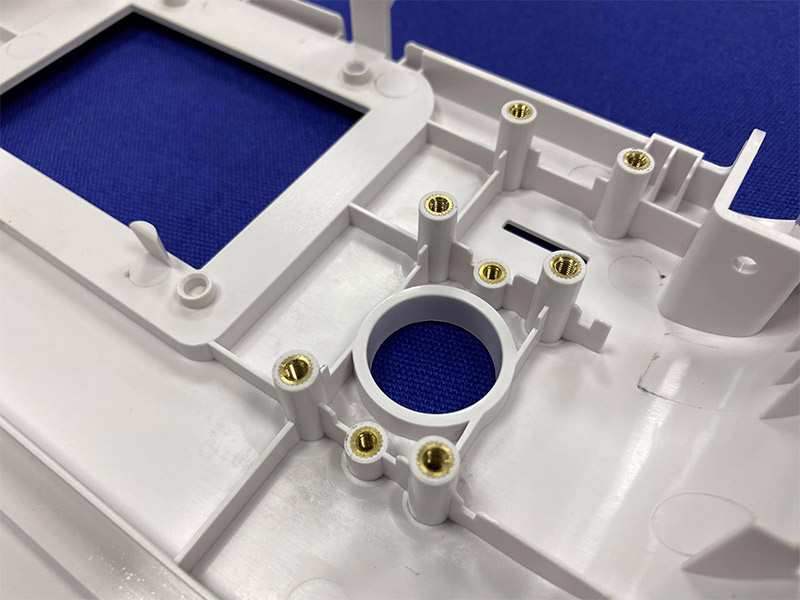

We have experience of machining more than 475 kinds of materials which includes materials for CNC machining car parts. At LJZ CNC car parts manufacturer, we are equipped with a spectrum analyzers to ensure the authenticity of raw materials. Common materials of auto parts that we work with are aluminum, China stainless steel machining, copper, brass, PVC, POM, NYLON, PEEK, etc.

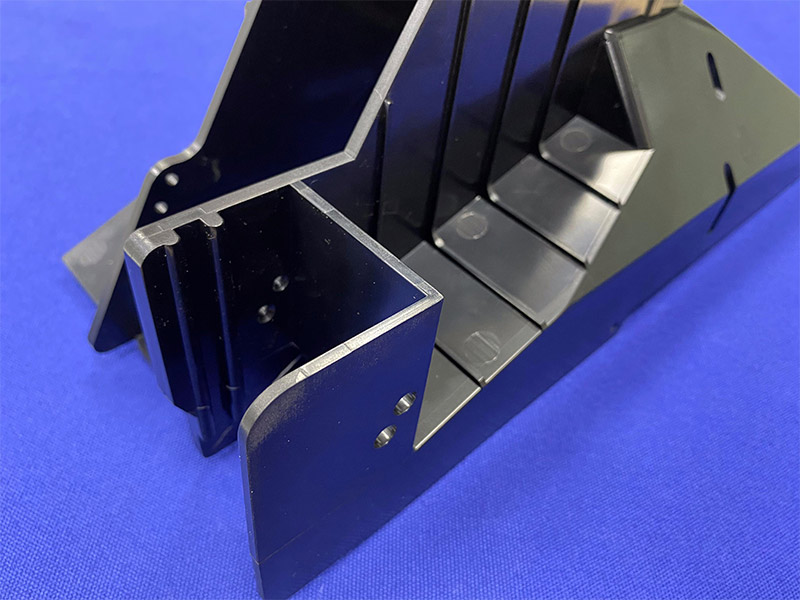

Many CNC auto parts will be requested for corresponding surface treatments to enhance the corrosion resistance and wear resistance so as to increase the automotive machining service life. Common surface treatments for CNC machined auto parts include: blackening, electroplating surface finish, anodizing, laser engraving, silk screen, and so on.

Rapid Prototyping

Customized auto rapid CNC prototyping and parts including performance parts and aftermarket parts. Without sacrificing development speed, prototyping to reduce design risks.

Mass Customization

Customize more diversified and customized automotive functions. Through our precise Siwss machining and automotive precision plastic injection molding China process, we can quickly occupy the market.

Tools and Fixtures

Improve the manufacturing process and create higher automation and simplified assembly of components through custom fixtures.

Assembly line components

Fixtures

Enclosure and housing

Plastic dashboard components

After-sales parts

Lens and lighting components

And more

ISO 16949 standard, PPAP, FMEA and FAI reporting are available for automotive customers basically demand.

Provide technical consultation, pre-review of drawings, structural analysis, risk assessment, constructive design suggestions, cost analysis and other services.

475 kinds of materials + 30 kinds of processing technology + 21 kinds of surface treatment + customized packaging

Contact us for more details from CNC auto parts manufacturers, or simply start with a free quote now!

Related Industries

Related Machining Service