There's a wide range of available materials in CNC machining and moldings, and choosing the right one for your application can be challenging. In the tables below, we summarized the information on the most commonly used CNC materials and plastic injection molding, in terms of their properties and mechanical characteristics. Using the information presented below can give you specific details for each available materials option and help you to identify the most suitable materials for your specific engineering needs, while keeping your project on budget. For further assistance in choosing the right materials, our manufacturing experts would love to help you at any time!

Material | Attributes | Tensile Strength | Elongation | Hardness | Manufacturing Process |

Aluminum | Corrosion resistance | 38-83 ksi | 1-17% | 55-95 HRB | Sheet Metal Fabrication |

Brass | Chemical resistance | 45-61 ksi | 23-30% | 32-36 HRB | Sheet Metal Fabrication |

Cobalt Chrome | Biocompatability | 130 ksi | 0.2 | 25 HRC | 3D Printing |

Copper | Corrosion resistance | 29-52 ksi | 5-50% | 40-110 HV | Sheet Metal Fabrication |

Low Carbon Steel | Ductile | 46-64 ksi | 15-39% | 42-69 HRB | Sheet Metal Fabrication |

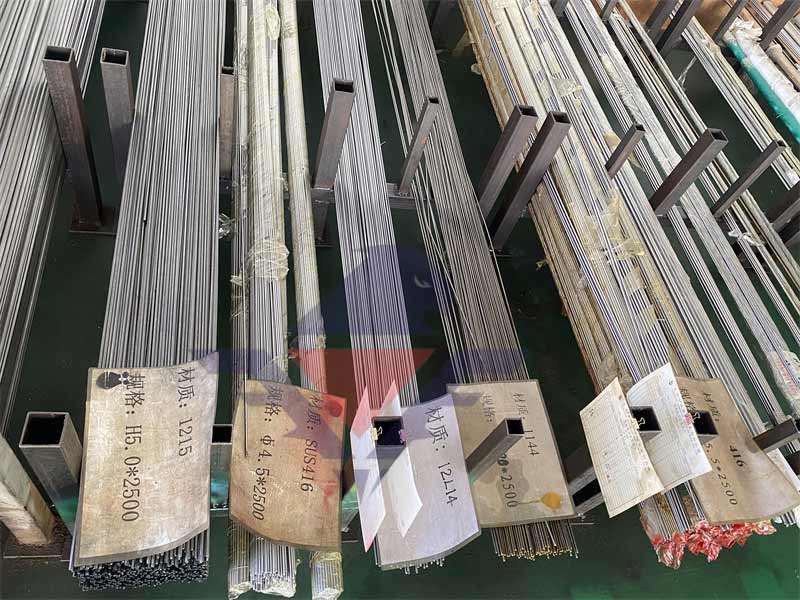

Stainless Steel | Corrosion resistance | 66-210 ksi | 5-56% | 35-101 HRC | Sheet Metal Fabrication |

Steel Alloy | Durability | 95 ksi | 0.25 | 92 HRB | CNC Machining |

Titanium | Corrosion resistance | 80-140 ksi | 10-20% | 30-39 HRC | CNC Machining |

Material | Attributes | Tensile Strength | Impact Strength | Heat Deflection | Durometer | Tear Strength | Elongation at Break | Manufacturing Process |

ABS | Cosmetic appearance | 5,000-12,000 psi | 3-7.5 ft-lb/in | 140-200°F | / | / | 20-30% | Injection Molding |

ABS-Like | Accuracy | 5.7-7.8 ksi | 0.79-0.91 ft-lb/in | 115-138°F | / | / | 6.1-20% | 3D Printing |

ABS/PC | Cosmetic appearance | 6,400-18,000 psi | 8-12 ft-lb/in | 140-210°F | / | / | 40-50% | Injection Molding |

CPVC | Flame resistance | 7,300 psi | 9 ft-lb/in | 198°F | / | / | 0.27 | CNC Machining |

ETPU | Crack resistance | 10,000 psi | 10 ft-lb/in | 280°F | / | / | 0.9 | Injection Molding |

HDPE | Durability | 2,900-4,500 psi | 80 ft-lb/in² | 130-250°F | / | / | 350-950% | Injection Molding |

LCP | Strength | 12,000-32,000 psi | 10 ft-lb/in | 525°F | / | / | 0.016 | Injection Molding |

LDPE | Crack resistance | 1,200-4,000 psi | 130 ft-lb/in² | 130-190°F | / | / | 400-500% | Injection Molding |

LLDPE | Flexibility | 1,400 psi | 190 ft-lb/in | 190°F | / | / | 6 | Injection Molding |

PA(Nylon) | Rigidity | 6,000-29,000 psi | 2-8 ft-lb/in | 180-350°F | / | / | 10-60% | Injection Molding |

PBT | Chemical resistance | 6,000-17,500 psi | 1-3 ft-lb/in | 200-420°F | / | / | 2-50% | Injection Molding |

Polycarbonate(PC) | Dimensional stability | 9,000-23,000 psi | 2-18 ft-lb/in | 150-300°F | / | / | 5-120% | Injection Molding |

PC-like | Accuracy | 6.8-11.6 ksi | / | 118-506°F | / | / | 0.7-13% | 3D Printing |

PC/PBT | Impact resistance | 6,300 psi | 17 ft-lb/in | 210°F | / | / | 3-120% | Injection Molding |

PEEK | Chemical resistance | 13,000-30,000 psi | 3.5-4.5 ft-lb/in | 300-625°F | / | / | 40-50% | Injection Molding |

PEI(U Item) | Heat resistance | 14,000-28,000 psi | 1-2 ft-lb/in | 350-420°F | / | / | 4-60% | Injection Molding |

PET | Chemical resistance | 7,000-23,000 psi | 0.5-8 ft-lb/in | 250-470°F | / | / | 1-45% | Injection Molding |

PETG | Durability | 7,250 psi | 3 ft-lb/in | 185°F | / | / | 100-130% | Injection Molding |

PMMA(Acrylic) | Optical clarity | 2,800-13,000 psi | 0.25-1 ft-lb/in | 180-215°F | / | / | 3-7% | Injection Molding |

POM(Acetal/ Delrin) | Chemical resistance | 6,000-22,000 psi | 0.75-2 ft-lb/in | 180-300°F | / | / | 10-40% | Injection Molding |

PP | Chemical resistance | 3,900-18,500 psi | 0.5-5.5 ft-lb/in | 120-300°F | / | / | 10-230% | Injection Molding |

PPE/PS | Dimensional stability | 8,500 psi | 2.5-8 ft-lb/in | 250-280°F | / | / | 15-30% | Injection Molding |

PP-Like | Accuracy | 4.4-4.7 ksi | 0.9-1.0 ft-lb/in | 120-300°F | / | / | 15-20% | 3D Printing |

PPS | Chemical resistance | 14,000-28,000 psi | 0.5-6 ft-lb/in | 400-500°F | / | / | 1-2% | Injection Molding |

PPSU | Chemical resistance | 10,100 psi | 13 ft-lb/in | 428°F | / | / | 40-120% | Injection Molding |

PS | Impact resistance | 4,200-11,000 psi | 0.25-7 ft-lb/in | 185-190°F | / | / | 3-30% | Injection Molding |

PSU | Corrosion resistance | 9,500-18,000 psi | 0.5-7 ft-lb/in | 300-350°F | / | / | 50-100% | Injection Molding |

PTFE(Teflon) | Chemical resistance | 2,900-5,000 psi | 2-6 ft-lb/in | 500°F | / | / | 210-400% | CNC Machining |

PVC | Chemical resistance | 7,800 psi | 0.8 ft-lb/in | 162-172° F | / | / | 1.5 | CNC Machining |

SB | Stiffness | 4,850 psi | 0.5-1 ft-lb/in | 150-160° F | / | / | 0.3 | Injection Molding |

UHMW | Durability | 5,800 psi | / | 116°F | / | / | 3 | CNC Machining |

Digital Photopolymer | Durability | / | / | / | 30-95 shore A, Rigid | 5-30 kg/cm | 200-270% | 3D Printing |

LSR | Cosmetic appearance | / | / | / | 30-80 shore A | 21-33 N/mm | 290-620% | Injection Molding |

LSR (Fluorosilicone) | Fuel and oil resistance | / | / | / | 60 shore A | 14 N/mm | 2.2 | Injection Molding |

LSR (Medical) | Biocompatability | / | / | / | 50 shore A | 47.4-52.4 kn/m | 4.99 | Injection Molding |

LSR (Optical) | Temperature resistance | / | / | / | 72 shore A | / | 0.8 | Injection Molding |

TPE/TPV | Flexibility | / | / | / | 35-87 shore A | 10-52 kn/m | 330-610% | Injection Molding |

TPU | Abrasion resistance | / | / | / | 83 shore A-43 shore D | 87-123 kn/m | 200-670% | Injection Molding |

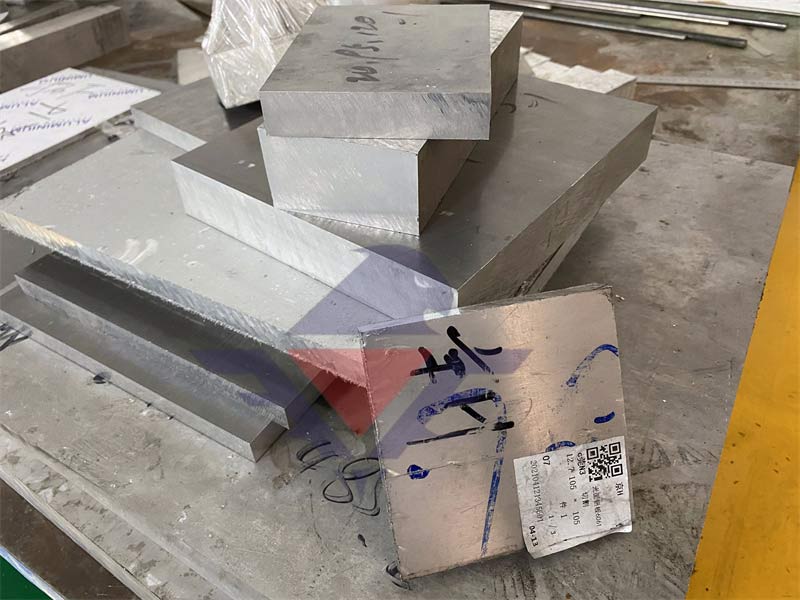

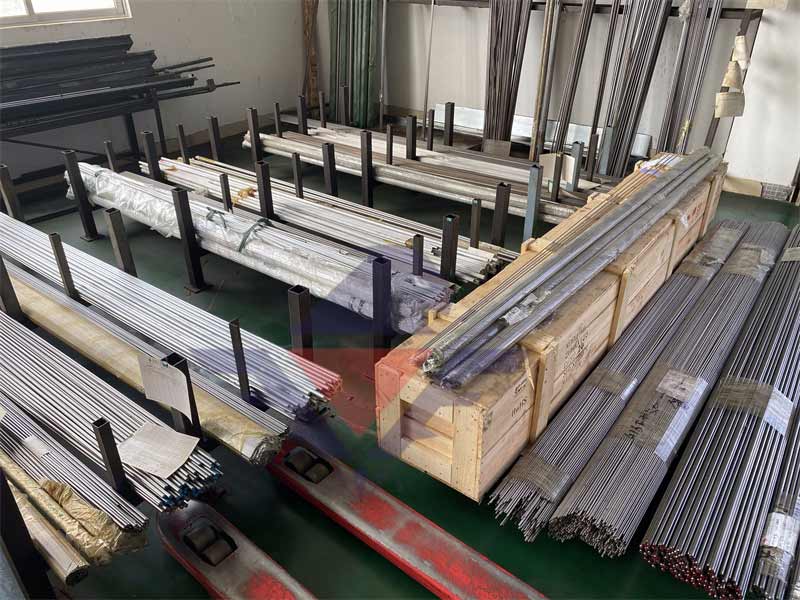

LJZ CNC materials stocks commonly used materials at any time for your urgent and volume needs. We aim to provide the most guaranteed CNC machining and plastic injection services for global OEMs for your on-demand manufacturing needs.