When discussing brass CNC machining, one must realize that not all brass is equal. Out of the various grades of brass, H59 and H62 are likely the two most prevalent brass alloys utilized in the industry for precision manufacturing.

Although they may seem similar to each other, choosing between H59 vs H62 can have a large effect on the performance of your part, your machining processes, and the affordability of the part.

Here, LJZ CNC will outline the differences between your two choices for brass grades so that you can better understand what will work best for you on your next CNC project.

Grade | Composition | Features |

H59 | ~59% Copper, 40% Zinc | Good strength, excellent machinability, low cost |

H62 | ~62% Copper, 38% Zinc | Higher corrosion resistance, better ductility, better for bending |

Both are free-cutting brass and both belong to the CuZn series of brass alloys, and both are readily available as rounds, plates, and bars for CNC turning and CNC milling.

Interested in learning more? Visit our Brass CNC Machining page for full capabilities.

✔ Very good machinability

✔ Can be used for higher-speed turning and milling

✔ Chips run short and clean

✔ Is often selected for automatic lathe (Swiss type) production

✔ Harder than H59 to machine

✔ Will require sharper tools, may have more chip buildup

✔ Will have a better finish assuming the right tooling and lubrication are utilized

Verdict:

For ease of use and on higher-speed mass production, select H59 Brass Machining. For parts that will consist of complex surfaces, or that it will be post-formed, select H62 Brass Machining.

Mechanical Properties

Property | H59 | H62 |

Tensile Strength | ~370 MPa | ~360 MPa |

Yield Strength | ~100 MPa | ~110 MPa |

Elongation | ~25% | ~30% |

Hardness (HB) | ~80 | ~70–80 |

H59: Stronger but less ductile

H62: Softer, better suited for bending, deep drawing

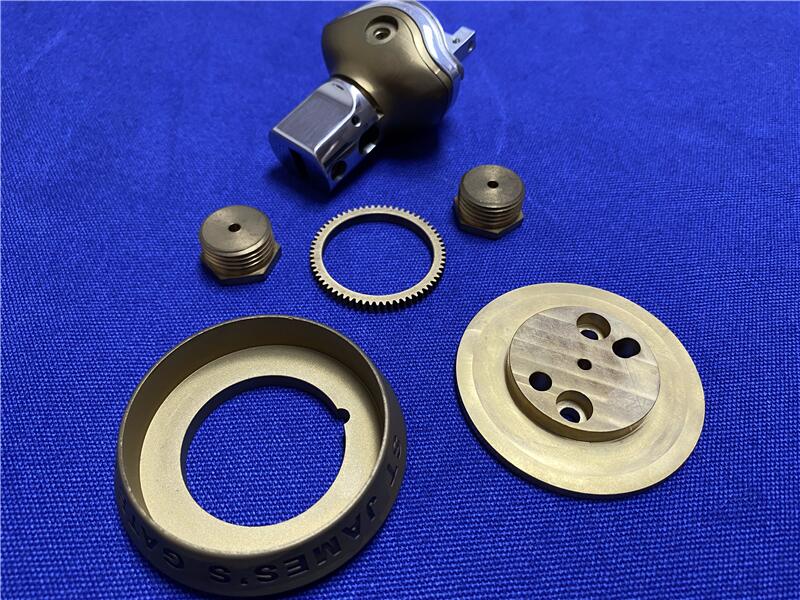

H59 Brass is preferred based on its lower cost and excellent Machinability. Examples of H59 and applications of H59 include:

Valve bodies

Connectors & fittings

Decorative hardware

Threaded components

Watch or small mechanical components

H62 Brass has a higher Copper content than H59. Examples of H62 applications include:

Plumbing parts

Marine equipment

Electrical terminals

Components that will be formed, bent, or reshaped.

Aspect | H59 | H62 |

Surface Finish | Good | Better polish capability |

Corrosion Resistance | Moderate | Higher |

Oxidation Resistance | Lower | Higher |

H62 has better long-term oxidation and corrosion resistance due to higher copper content, making it more suitable for outdoor or fluid-exposed environments.

If Your Project Requires… | Choose |

High machining speed & low cost | H59 |

Better bendability or forming | H62 |

Strong corrosion resistance | H62 |

Tight threads or high-volume turned parts | H59 |

Decorative appearance with polish | H62 |

At LJZ CNC Machining, we routinely assist clients with making choices between H59 and H62 with respect to the application of their part, expected performance, and budget constraints.

Whether you are producing custom fittings, sensor terminals, or medical connectors, LJZ CNC will help you refine the tooling, machining parameters, like:

Type of Tool and Coating

Feed rate and spindle speed

Lubrication program

Post-machining surface treatments

In short, we are not just a machining shop but your material collaborator.

Need Help with Brass CNC Machining?

If you are uncertain in identifying which grade of brass to use for your design, our engineers would be very happy to help you. We are also able to provide custom CNC machining on both H59 and H62 brass with very tight tolerances, quick lead times, and we can ship globally. Welcome to contact us now!