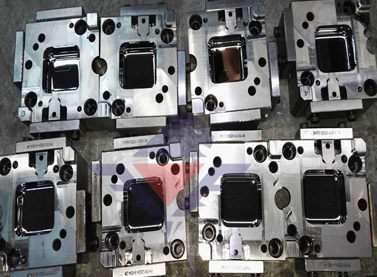

Mold and moldings are the best solution for mass production. Excellent molds not only have high precision but also have a long service life. The produced parts are also highly accurate and economical. Therefore, LJZ CNC mold making requires extremely high machining capabilities, especially for optical molds, which require super high-speed spindles and professional surface polishing skills to meet the rigorous standards of china cnc mold making.

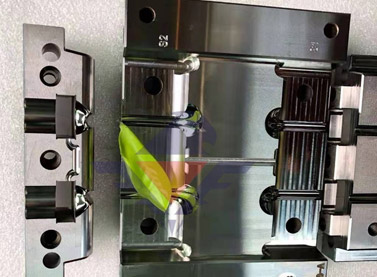

The high-speed 5-axis machine is used to machine complex cut pieces. At LJZ CNC, we use one 5-axis machine to manufacture complete custom parts for tool and mold making to improve the efficiency and precision.

The precision of WEDM can reach more than 0.005mm with surface roughness Ra0.1μm. In addition, special materials such as tungsten steel can be processed as well.

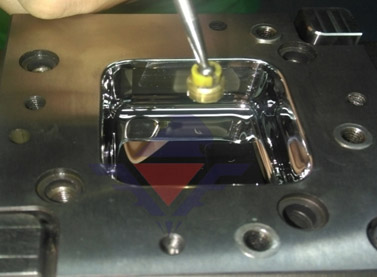

Small holes or deformed holes can be realized. The minimum EDM machining accuracy at LJZ CNC, a leader in china cnc mold making, can reach 0.005mm with a surface 1μm and depth tolerance within 2μm. Also, hard materials such as tungsten steel can be processed.

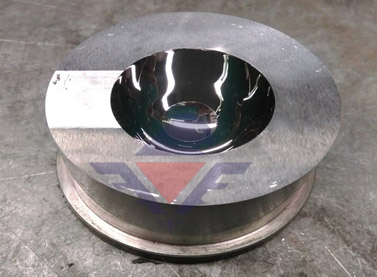

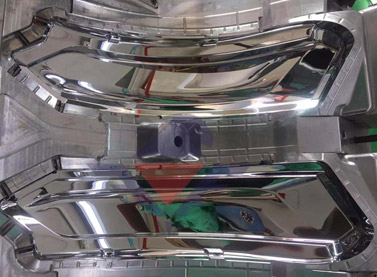

LJZ CNC grinding and polishing service, essential for high-precision china cnc mold making, is suitable for optical moldings, LED, and medical mold products. The surface roughness is Ra0.3μm, concentricity is less than or equal to 0.005mm, and straightness is less than or equal to 0.002mm.

Each industry has different requirements for the service life of molds, so the material selection for cnc mold making is very important—a critical factor that determines the quality and durability of molds crafted through china cnc mold making. Years of experience in mold processing give us the confidence to ensure the products' accuracy and longer service life. The materials commonly used in LJZ CNC include aluminum, stainless steel, steel, copper, T7, T8, T12, 6CrW2Si, 5CrMnMo, Cr12, Cr12MoV, etc.

Surface finishes for cnc molding include sandblasting, mirror polishing, and texturing.

Contact us today for engineering support on the mold and moldings project!

Related Industries

Related Machining Service